Goldstone International Private Limited

Goldstone International Private Limited

Let's Create, Innovate, Succeed Together!

Let's Create, Innovate, Succeed Together!

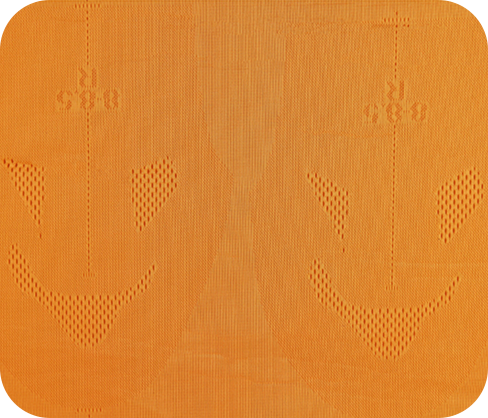

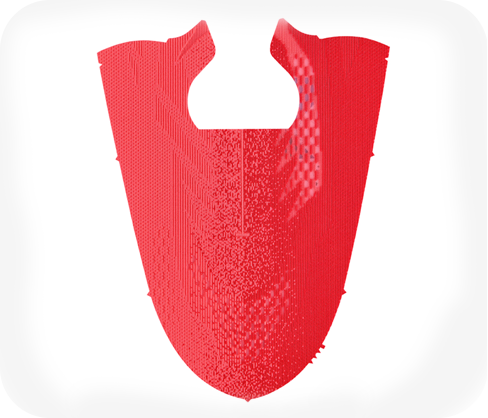

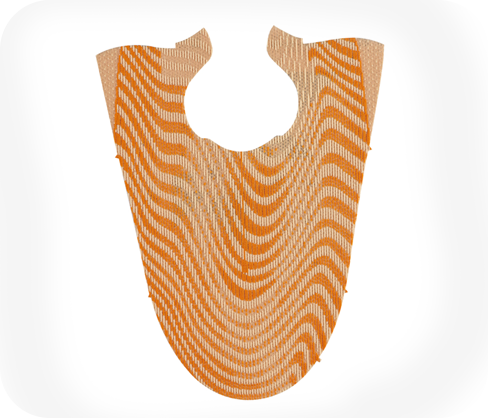

Warp Knitting Machine double is bar is for short pile fabric. The warp knitting machine could be used chemical fibres such as polyester, polyamide, acrylic, polypropylene & viscose or natural fibres such as cotton yarn, blended yarn etc. War knitting Machine is idle to produce short pile fabrics, which pile height is with in 6 mm or space fabric with thickness of 0.6 – 12 mm (calling sandwich fabric). Warp knitting machine is equipped with jacquard, machine could change & produce Tri dimensional designs rapidly.

It double needle bar machine for short pile fabrics. It could use chemical fibers such as polyester, polyamide, acrylic, polypropylene and viscose or natural fibers such as spinning cotton yarn, blended yarn etc, to produce short pile height is within 6mm or space fabrics with thickness of 0.6-12mm called us (sandwich fabrics). Equipped with Jacquard, machine could change and produce tri-dimensional designs repidily. By using different yarns, machine could produce different fabrics with vivid-colored designs which could be widely used for garments, shoe fabrics, home textiles fabrics and auto cushions etc.

| Machine Type | E2295/6 | E2295/7 | E2295/8 | E2295/-J6/1 | E2295/-J6/2 | E2295/-J7/1 | E2295/-J5/3 |

|---|---|---|---|---|---|---|---|

| Needle | Latch Needle | ||||||

| Gauge | E16, E22, E24, E26, E28 | E22, E24 | |||||

| Working width(mm) | 84*\ 136*\ 154*\ | ||||||

| No. of Guide Bars | 6 Bars (2 Ple Bars) | 7 Bars (3 Ple Bars) | 8 Bars (3 Ple Bars) | 5 Ground Bars (1 Ple Bars) | 4 Ground Bars (2 Ple Bars) | 6 Ground Bars (1 Ple Bars) | 2 Ground Bars (3 Ple Bars) |

| Trace Plate Distance(mm) | 0.6 - 12 | ||||||

| Max Knitting Speed (courses/min) | 800 | 750 | 700 | 550 | 500 | 550 | 450 |

| Pattern drive device | N - type Pattern drive device or EL device | ||||||

| Let-off Device | EBC Let-off System | ||||||

| Take-up Device | Electronic Take-up Device | ||||||

| Max fabric batching diameter (mm) | 1270 | ||||||

| Dia of sectional beam (mm) | 1016*535 (40*21) or 762*535 (30*21) | ||||||

| Total machine power (kw) | 20 | ||||||

The prices varies from model to model. We deals in different type of machines for making different products. You may connect through enquiry form.

On confirmation of order, it takes 45 -50 days to deliver. If the stocks is available, we can dispatch next day.

It is for six months for electronic parts & one year for mechanical parts.

Flat knitting machines require regular cleaning and oiling of key components. Needles may need periodic replacement as well as other wear parts.

Manufacturing brands differentiate themselves through quality, technology, innovation, customization, customer service, pricing, brand reputation, and other factors like sustainability and social responsibility.

We have sold out more than 2000 machines in all over India and more than 4 hundred flat knitting machines for Shoe Upper in Delhi NCR to major player of shoe manufacturing.