Goldstone International Private Limited

Goldstone International Private Limited

Let's Create, Innovate, Succeed Together!

Let's Create, Innovate, Succeed Together!

A process that involves melting EVA granules and injecting the fluid EVA into a closed mold. The mold is then opened to extract the solid piece. Eva Injections comes with 2,4,6,8,10 Stations.

| Model | JT-DS1808 |

|---|---|

| Overall Dimensions | 1500 x 1100 x 1500mm |

| Work Bench | 900 x 360mm |

| Overall Machine Weight | 350kg |

| XYZ Working Stroke | 1020 x 440 x 35mm |

| Driving Method | Ball Screw + Servo Motor |

| Rapid Movement Speed | 40m/min |

| Repeat Positioning Accuracy | 0.02min |

| System | Lechuang |

| Programming Method | Teaching Programming |

| Power Supply | AC220V 50HZ |

| Power | 500W |

| Air Source | 0.6mpa |

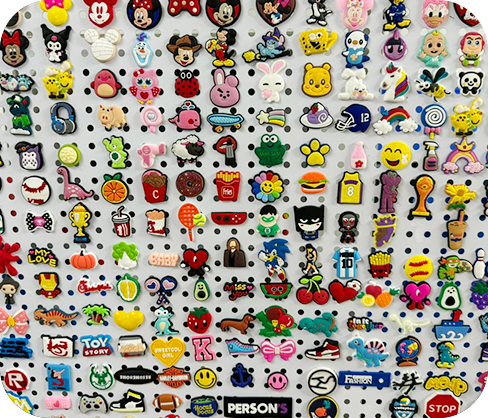

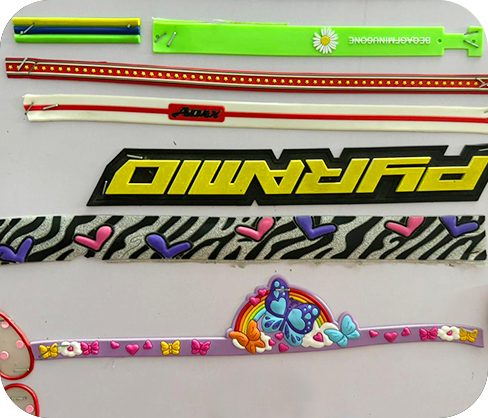

JT-DS1808 18 colors Automatic Plastic Dropping Machine, Suitable for uppers of slipers, shoe accessories, shoe straps, PVC handicrafts and clothing & bags etc. PVC products.

The prices varies from model to model. We deals in different type of machines for making different products. You may connect through enquiry form.

On confirmation of order, it takes 45 -50 days to deliver. If the stocks is available, we can dispatch next day.

It is for six months for electronic parts & one year for mechanical parts.

Flat knitting machines require regular cleaning and oiling of key components. Needles may need periodic replacement as well as other wear parts.

Manufacturing brands differentiate themselves through quality, technology, innovation, customization, customer service, pricing, brand reputation, and other factors like sustainability and social responsibility.

We have sold out more than 2000 machines in all over India and more than 4 hundred flat knitting machines for Shoe Upper in Delhi NCR to major player of shoe manufacturing.