Goldstone International Private Limited

Goldstone International Private Limited

Let's Create, Innovate, Succeed Together!

Let's Create, Innovate, Succeed Together!

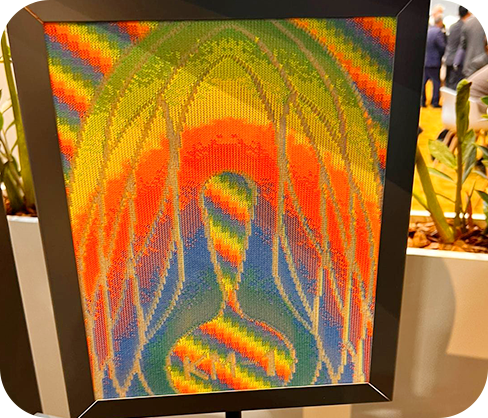

Weaving Machine is suitable for all kinds of double warp fabric weaving widely used for the production of shoes vamp fabric, curtail fabric, suitcase fabric & labels etc. Weaving machine has Staubli jacquard with Itema Loom. It has automatic thermal cutting & thermoforming.

| Speed | 600 rpm(max) |

|---|---|

| Machine width | 1900mm / 2300mm |

| Control system | Electronic system with microprocessor |

| Wrap let-off | Electronic let-off motion with tensioning device |

| Stop motion | Electronic machine stops automatically when warp or weft breaks |

| Take-up | Electronic |

| Weft density | Electronic density adjustment from 2- 200picks/cm |

| Weft selector | 8 weft color selector(12 weft color as option) |

| Weft finding | Automatic weft pick finding with variable program |

| Lubrication | Centralized lubrication system |

| Warp beam | Diameter of 600mm / 800mm |

| Cloth take-up | Diameter of 600mm (max) |

| Power | 7.5kw of main motor |

| Weft Feeder | Iro star G2 (Iro Laser G2 as alternative choice) |

| Dimension | W5700mm / L2200mm / H4000mm |

| Weight | Approx. 6500kg |

| Power Supply | 3 phase, 380V, 50Hz, +10% tolerance |

| Model | Staubli LXM jacquard |

|---|---|

| Hook | 2688/5376 hooks |

| Controller | TC8 control unit |

| Harness | Italy RTS harness cord, Germany Hornex |

| Power | 2.5kw(max) |

| Weight | Approx. 1200kg |

The prices varies from model to model. We deals in different type of machines for making different products. You may connect through enquiry form.

On confirmation of order, it takes 45 -50 days to deliver. If the stocks is available, we can dispatch next day.

It is for six months for electronic parts & one year for mechanical parts.

Flat knitting machines require regular cleaning and oiling of key components. Needles may need periodic replacement as well as other wear parts.

Manufacturing brands differentiate themselves through quality, technology, innovation, customization, customer service, pricing, brand reputation, and other factors like sustainability and social responsibility.

We have sold out more than 2000 machines in all over India and more than 400 hundred flat knitting machines for Shoe Upper in Delhi NCR to major player of shoe manufacturing.