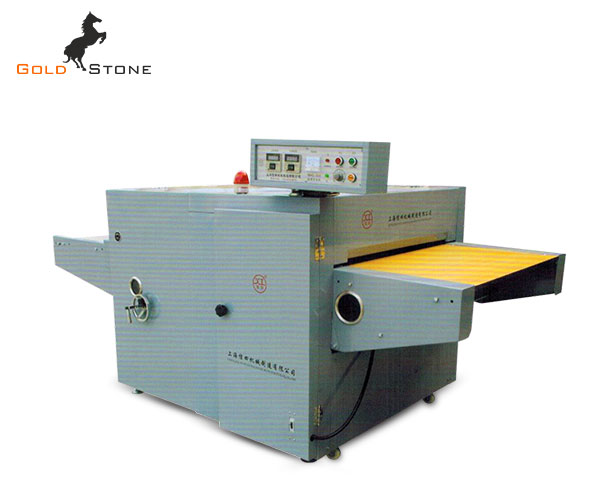

Technical Features

- A continuous fusing system increases productivity.

- Equipped with wheels for convenient mobility.

- The PCB and micro switch control the upper and lower belts automatically and extend the duration of the belt.

- Pressure rollers are made of silicone, which ensures the power of pressure giving is stable and equal.

- Electronic constant temperature control system, accurate temperature.

- There are 6 heaters to distribute the heat evenly, and they can be used on all fabrics.

- With the cooling fan and mesh conveyor belt, which has the best cooling effect.

- Equipped with an automatic cooling timing shutdown system.

- Standard with a strong spring-pressure mechanism.

- Specially designed clean rod to clean the belt completely, and it is easy to replace once the rod gets dirty.

- With a frequency conversion mechanic to control speed, running smoothly and saving more energy.

- Optional: NH1600/1800/2000A: Air (Pneumatic) Pressure; Basket of cloth/ Automatic feeding machine; winding machine/infrared edge cloth rolling machine.

Technical Parameter

| Model | NHG-1600 | NHG-1800 | NHG-2000 |

|---|---|---|---|

| Power Supply | 3P/380V | ||

| Motor | 200W | ||

| Power | 16kw | 18kw | 20kw |

| Max Pressure | 4kg/cm2 | ||

| Temperature | 200°C | ||

| Fusing Width | 1600mm | 1800mm | 2000mm |

| Fusing Time | 10-34sec | ||

| L x W x H Dimensions(mm) | 2350 x 1180 x 1400 2000 x 810 x 1290 |

2550 x 1180 x 1400 2200 x 810 x 1290 |

2750 x 1180 x 1400 2400 x 810 x 1290 |

| N,W,G,W | 800 / 1000 | 850 / 1050 | 900 / 1200 |

What is the price?

The prices varies from model to model. We deals in different type of machines for making different products. You may connect through enquiry form.

What is the delivery period?

On confirmation of order, it takes 45 -50 days to deliver. If the stocks is available, we can dispatch next day.

What is the warranty on the machine?

It is for six months for electronic parts & one year for mechanical parts.

What types of services does this company provide?

- Installation and Commissioning of new machine

- AMC service to our customers after completion of guarantee periods.

- Spare parts service including needles, sinker, jack mechanical and electronic spare parts.

What maintenance does a flat knitting machine require?

Flat knitting machines require regular cleaning and oiling of key components. Needles may need periodic replacement as well as other wear parts.

How does a manufacturing brand differentiate itself from competitors?

Manufacturing brands differentiate themselves through quality, technology, innovation, customization, customer service, pricing, brand reputation, and other factors like sustainability and social responsibility.