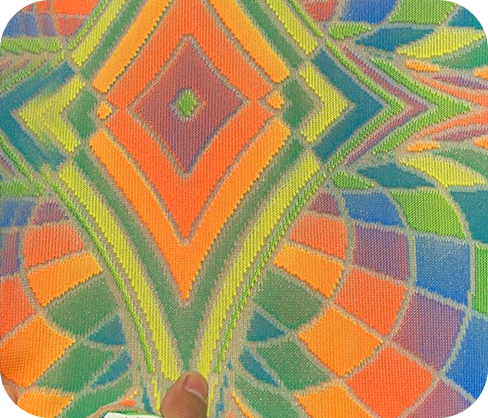

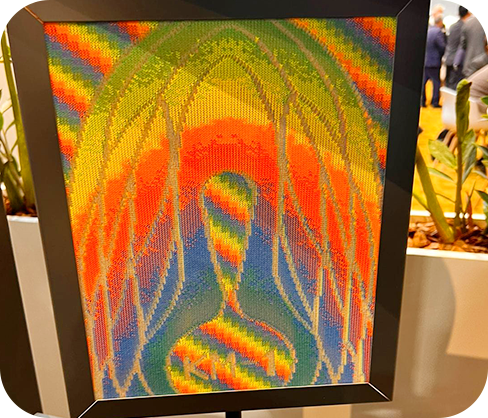

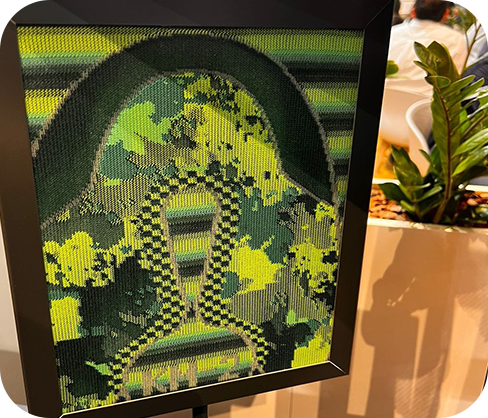

The weaving machine is suitable for all kinds of double warp fabric weaving and is widely used for the production of shoe vamp fabric, curtain fabric, suitcase fabric, labels, etc. The weaving machine has a Staubli jacquard with an Itema loom. It has automatic thermal cutting & thermoforming.

Technical Features

- Suitable for all kinds of double warp fabric weaving, it has been widely used in production of shoes vamp fabric, curtain fabric, suitcase fabric, etc.

- Adapting a fast-change system for both up and down AMS makes it easier to operate for warp tying.

- Upgrade the double backrest system with enhanced beating motion to ensure the high-quality weaving of the double-layer fabric suit for high-density fabric weaving and also provide easy operation.

- New special design of full-width temple, which is more suit for double heavy fabric

- The integral machine support frame with upper beam and jacquard requires very little ground space and is the most space-saving twin-beam jacquard fabric weaving loom.

- Direct drive motor: the main drive is based on an electronic and brushless motor technology, which provides easy operation and energy saving.

Technical Parameter

| Speed | 600 rpm(max) |

|---|---|

| Machine width | 1900mm / 2300mm |

| Control system | Electronic system with microprocessor |

| Wrap let-off | Electronic let-off motion with tensioning device |

| Stop motion | Electronic machine stops automatically when warp or weft breaks |

| Take-up | Electronic |

| Weft density | Electronic density adjustment from 2- 200picks/cm |

| Weft selector | 8 weft color selector(12 weft color as option) |

| Weft finding | Automatic weft pick finding with variable program |

| Lubrication | Centralized lubrication system |

| Warp beam | Diameter of 600mm / 800mm |

| Cloth take-up | Diameter of 600mm (max) |

| Power | 7.5kw of main motor |

| Weft Feeder | Iro star G2 (Iro Laser G2 as alternative choice) |

| Dimension | W5700mm / L2200mm / H4000mm |

| Weight | Approx. 6500kg |

| Power Supply | 3 phase, 380V, 50Hz, +10% tolerance |

Jacquard

| Model | Staubli LXM jacquard |

|---|---|

| Hook | 2688/5376 hooks |

| Controller | TC8 control unit |

| Harness | Italy RTS harness cord, Germany Hornex |

| Power | 2.5kw(max) |

| Weight | Approx. 1200kg |

What is the price?

The prices varies from model to model. We deals in different type of machines for making different products. You may connect through enquiry form.

What is the delivery period?

On confirmation of order, it takes 45 -50 days to deliver. If the stocks is available, we can dispatch next day.

What is the warranty on the machine?

It is for six months for electronic parts & one year for mechanical parts.

What types of services does this company provide?

- Installation and Commissioning of new machine

- AMC service to our customers after completion of guarantee periods.

- Spare parts service including needles, sinker, jack mechanical and electronic spare parts.

What maintenance does a flat knitting machine require?

Flat knitting machines require regular cleaning and oiling of key components. Needles may need periodic replacement as well as other wear parts.

How does a manufacturing brand differentiate itself from competitors?

Manufacturing brands differentiate themselves through quality, technology, innovation, customization, customer service, pricing, brand reputation, and other factors like sustainability and social responsibility.